Plan of attack for small company supplier negotiations

How emerging life sciences organizations can create value with suppliers

In the rush to manage drug development and commercialization timelines, emerging life sciences companies may feel the need to quickly enter into supply agreements. However, by taking time to properly define specific business requirements, understand the supply market and manage the negotiation process, a company can minimize risk by controlling supplier quality and avoiding hidden costs. How a company manages their sourcing process will determine how they “buy on value and not on price.”

While emerging companies want to build valuable supplier relationships, some team members’ prior experience with a large company’s sourcing bureaucracy can hinder their current ability. By “letting go” of past practices and applying strategic sourcing practices aligned with their current business requirements, an emerging biopharma company can negotiate supply agreements to meet development timelines, quality requirements and cost constraints.

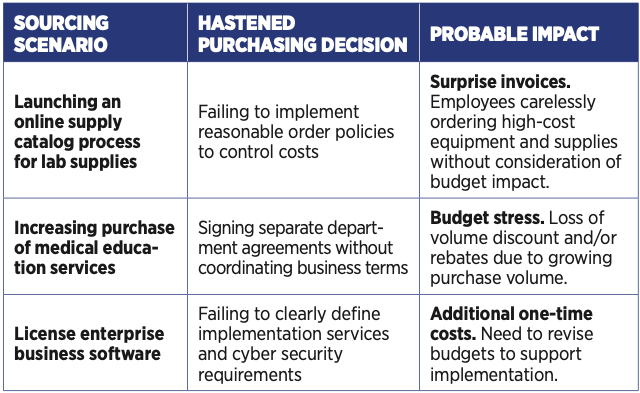

Consider these scenarios which describe “hastened purchasing decisions” that can adversely impact an emerging company’s ability to develop products and grow:

Importance of value

Value is a combination of price, cost and how a good or service supports a company’s growth. It is one thing to recognize that purchasing low-cost lab equipment and supplies is not valuable to a company if their equipment will not help them properly run a design of experiment. However, spending top dollar on lab equipment and supplies will be inefficient if the equipment is unused and supplies go out of date.

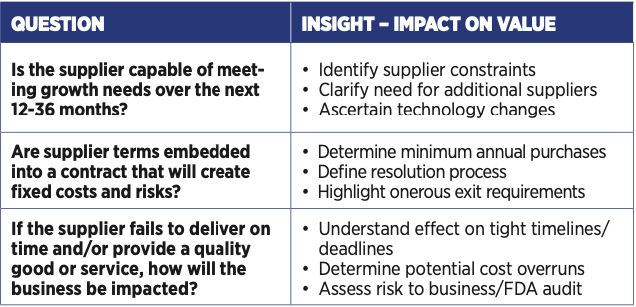

To understand the value of supply contracts, consider the following questions to determine the parameters that will create a valuable supplier relationship:

Details matter—prevent terrible contracts

Unfortunately, we hear about terrible contracts too often. To avoid this, buyers should practice “caveat emptor” by managing their contract process. Thinking a supplier’s terms are adequate and standard for all customers is a grave mistake leading to hidden costs and increased risks. Realizing this, good companies take time to properly manage the sourcing, negotiating and contracting process to prevent bad contracts from being implemented. While emerging companies may lack an organized sourcing and contract management systems, they have an opportunity to develop an efficient process to link systems, polices and organizational responsibilities together.

By building relationships with suppliers through a simple but organized sourcing process, an emerging company can create value and serve the needs of its patients.

About the Author

Dave Stowe is senior procurement advisor at Tunnell Consulting. He can be reached at [email protected].