Active packaging protects oral solid formulations

New technologies offer improved shelf life for moisture- and oxygen-sensitive oral solids

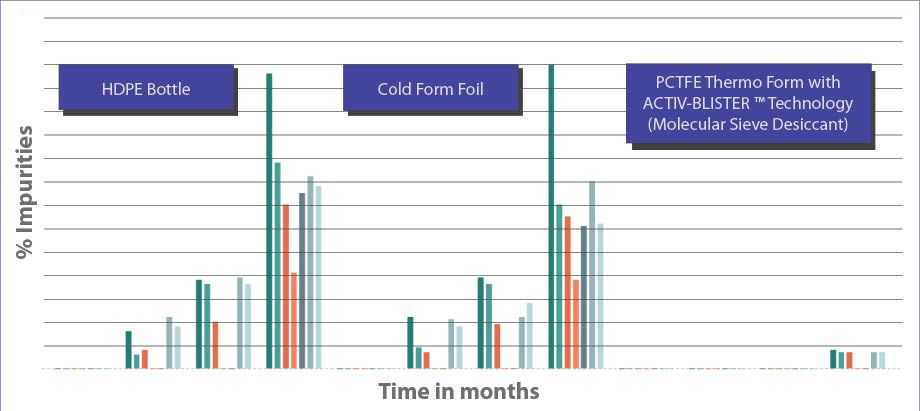

Fig. 1. Comparing impurity levels in (left) HDPE bottle; (center) cold-form foil; (right) CSP Activ-Blister with PCTFE thermoform and molecular sieve desiccant. Data and graphic courtesy Tekni-Plex

Despite advancements in, and the proliferation of, other drug delivery platforms, oral solid dose (OSD) drug delivery–a category that comprises both capsules and tablets–remains the most popular delivery method in use today. In fact, six out of the 10 most widely prescribed pharmaceuticals are OSD. Reinforcing this continued dominance, the US FDA Center for Drug Evaluation and Research’s (CDER) annual list of novel drugs, indicates that 24 of 45 such innovative new products approved in 2015 are OSDs. This market predominance is predicted to continue, even with the emergence of new delivery options such as transdermal applications.

The expansion is predicated, in part, by expanding OSD technologies such as semi-solid and powder-blend, which enable more challenging and potent APIs as well as modified release specifications, such as sustained and controlled release. Oral disintegrating tablets are yet another technology that is driving OSD growth. However, innovation often has complications: these new valuable, highly specialized technologies can–perhaps even more so than traditional capsules and tablets–result in products that face significant stability challenges, especially from moisture, oxygen, hydrocarbons and other gases, or a combination of these. Among other unfortunate aspects, this instability can also come from reactive impurities, such as formaldehyde and formic acid, which has been implicated in the degradation of drug products and also cross-linking in gelatin capsules.

These advanced delivery technologies have created the need for new and specialized active packaging solutions that adequately address the formidable stability challenges that have arisen simply through the march of pharmacological progress. Market demand is growing for solutions that not only protect products from unwanted moisture and oxygen ingress, but also proactively remove moisture and gases within the package headspace as well as reactive impurities and off-gassing from increasingly sophisticated—and, correspondingly, costly and valuable—OSD products.

The age-old argument: bottles vs. blistersBottles and blisters are, of course, the OSD package options of choice, with each facing its own headspace management challenges. These challenges stem from the headspace at the time of production, as well as ingress over time and in various, often widely differing, environmental conditions. While bottles have long dominated the US market (not the case in the EU), there is growing demand for blisters, from both existing and new drugs, driven by both consumer preferences and regulatory requirements. However, this is creating headspace management issues that have limited solutions.

Since they offer individual unit-dose compartments, blisters are preferable for situations where safety and patient compliance are of paramount concern. Blisters offer patients easy verification and indication that a dose has been taken, and also offer ease of portability. In addition, blisters typically feature tamper evidence superior to bottles and, by removing the need for a bulk container, they eliminate the traceability gap by providing improved track and tracing in pharmacy, hospital and research (i.e., clinical trial) settings.

Reduced possibility of accidental misuse is another check in the pro-blisters column, as is superior adaptability of the unit dose for clinical trial needs, which often include the need for expanded label content, high visibility, and built-in track and trace features. Each of these factors and more showcases why, when compared to bottles overall, blister packaging best addresses regulatory concerns pertaining to supply chain security, clinical trial reliability and hospital traceability.

Since each dose is housed in an individual package until its use, there is an inherent advantage compared with bottles. Still, challenges exist. Most relevant to the topic at hand is a question that is seen as an obstacle to using blisters: How can blisters offer effective and efficient product protection from oxygen, moisture and off-gassing? This is particularly important in extreme climates, such as Climate Zones III (hot and dry) and IV (hot and humid).

Fig. 2. The Activ-Blister technology addresses offgassing in the headspace of a blister package. Credit: CSP

Blister packaging’s headspace challengeDespite the larger amount of headspace, bottles have a simpler solve than blisters for headspace management. Unlike blisters, bottles can easily incorporate sachets and canisters to provide desiccant and/or scavenger capabilities; adding barrier technology to the actual bottle material can further mitigate degradation. Advanced protection solutions for blisters, outside of barrier technology, are less apparent, are often non-standard, impact product and supply chain costs, and can add steps to the customer experience.

Although the headspace within individual blisters may be small, it is nonetheless more than enough to significantly impact shelf life. In order to reduce ingress, aluminum foils and high barrier thermoforms are used, but headspace moisture, gases and impurities can persist.

Nitrogen purge is a popular headspace management option but can be difficult to validate, requires additional monitoring in production, and does not protect against off-gassing. In addition, since it does not protect against ingress, it must be paired with high barrier materials. Secondary (so-called “tropical”) packaging comprising sachets and fishbone designs with desiccant pucks are active solutions that address the shortcomings of purging but add size and complexity to the packaging, which in turn adds production and shipping costs. Similar to purging, tropical packaging does not protect against off-gassing.

And here lies blister packaging’s desiccant and scavenge challenge: How can blister applications address headspace management efficiently and effectively to enable the growing customer and regulatory demand for this application?

Get smart (packaging)Smart packaging can be divided into two distinct areas: active packaging, which provides proactive functions such as moisture and oxygen absorption; and intelligent packaging, which communicates product changes and other information. The latter communicates something, while the former actually does something.

For the purposes of this article, let’s limit our discussion to those situations requiring active packaging–specifically, when pharma products need more than just protection and instead require the proactive removal of moisture, oxygen, hydrocarbons and reactive impurities such as formaldehyde, etc.

This past year saw the introduction of a promising packaging solution offering a novel approach to headspace management for protecting sensitive OSD pharmaceuticals from moisture, oxygen and other gases, as well as impurities from the capsules and tablets, themselves. Branded as Activ-Blister solutions, the innovation controls the internal atmosphere of each blister cavity, allowing for better product performance and shelf life, without the use of purging or secondary packaging. The patented and proprietary technology provides desiccant and scavenging capabilities to traditional and existing blistering films and designs.

Specifically, an extruded polymer a mere 0.3 millimeters thick, die-cut to fit within any blister shape and size, is adhered to the blister’s lidding via heat-staking just prior to sealing, sitting beneath the capsule or tablet and completely within the sealed space of the individual blister. The process uses no adhesives, which themselves could generate the sort of additives the technology seeks to remove; adhesive cost also is avoided.

This type of active blistering can be made suitable for any OSD packaged on thermoform-fill-seal and fill-seal equipment; it is also compatible with child-resistant and cold-form designs. Using silica gel or molecular sieve (two substances widely used for their scavenging properties) technology, outfitted blisters can be customized to absorb tailored amounts of water vapor. Using scavenger technology, blisters can absorb oxygen or targeted gases and impurities, to levels lower than those achieved by purging. Greater still, these extruded polymers can be engineered to provide combination management of moisture and gas. All options can be produced in shapes and sizes to accommodate nearly any tablet and capsule size.

For pharmaceutical manufacturers and contract packagers, the cost of incorporating such active scavenging blister solutions is, typically, more than offset by alternative measures taken to best ensure premium moisture protection, especially when compared to purging and secondary packaging. Further, Activ-Blister solutions may allow a product to move from larger cold-form packages to a thermoform that offers a smaller footprint (up to a 40-60% size reduction) and provides visibility of the capsule or tablet for the customer.

Holistic approachExtending shelf life, reducing returns and optimizing package design is important to any OSD application. All of these challenges are magnified in Climate Zones III and IV, making a truly global packaging and supply chain operation extremely difficult to serve. Many factors must be taken into account, including headspace at the time of packaging, ingress, and off-gassing from API and excipients. Often, there is a pile-on effect that happens throughout the product’s production, shipping and shelf life, and all of these issues can be exacerbated even further in the high humidity climate zones.

Simulated modeling can examine the impact of Activ-Blister solutions with various blister materials and designs. Attractive options can then be examined through prototyping and shelf life testing to determine both the drug product and the desiccant or scavenger performance. This process can provide relatively quick iterations and data to optimize package design.

Plus, experience has shown some unexpected benefits of Activ-Blister technology. In one example, impurities were seen in an HDPE bottle application and persisted even in a cold form blister. More interesting, scavenging oxygen and other gases also did not impact impurity levels. Surprisingly, it was ultimately found that Activ-Blister technology using a molecular sieve (MS) desiccant was able to sufficiently reduce the impurities. Even better, this performance was achieved in a thermoform design, providing capsule visibility and minimized footprint capsules. (Fig. 2.)

ConclusionUtilizing new packaging solutions that actively scavenge for moisture, oxygen and other gases—as well as degradation products such as VOCs—in blister headspace, products that are normally packaged in bottles with desiccant sachets can now be thermoformed into blister cards without sacrificing protection. This move from bottle to blister can effectively eliminate the added costs associated with gas flush/purge and secondary packaging with sachets, etc.

Active blistering technology enables pharma manufacturers to achieve headspace management comparable to existing bottle options. It can extend the shelf life of alu alu and thermoforms by reducing, and in some instances eliminating, moisture and gases in existing headspace and from potential ingress throughout the supply chain. Use of this groundbreaking technology also reduces packaging complexity and costs by eliminating the need for purging, secondary and fishbone packaging. Moving from cold form to thermoform also reduces material costs and results in a smaller footprint, and its adhesive-free heat-staking helps eliminate associated off-gassing and expense.

ABOUT THE AUTHOR

Craig Voellmicke is VP of Business Development for CSP Technologies, Inc. (www.csptechnologies.com), which focuses on pioneering new packaging technologies and designs that ensure product protection and enhance brand recognition. The company’s services include custom product design, development and manufacturing. Its portfolio of products falls into four categories: vials, films and blisters, molded components, and specialized packaging solutions.

Save

Save